Progressive Cement

A CleanTech breakthrough – to fight climate change – building on a 2000-year-old innovation from the Roman Empire.

Cement creates 8% of Global CO2 emissions.

We are changing that.

Types of Pozzolan

Ground Glass Pozzolan and Natural Pozzolan

Our Groundbreaking Ground Glass Pozzolan

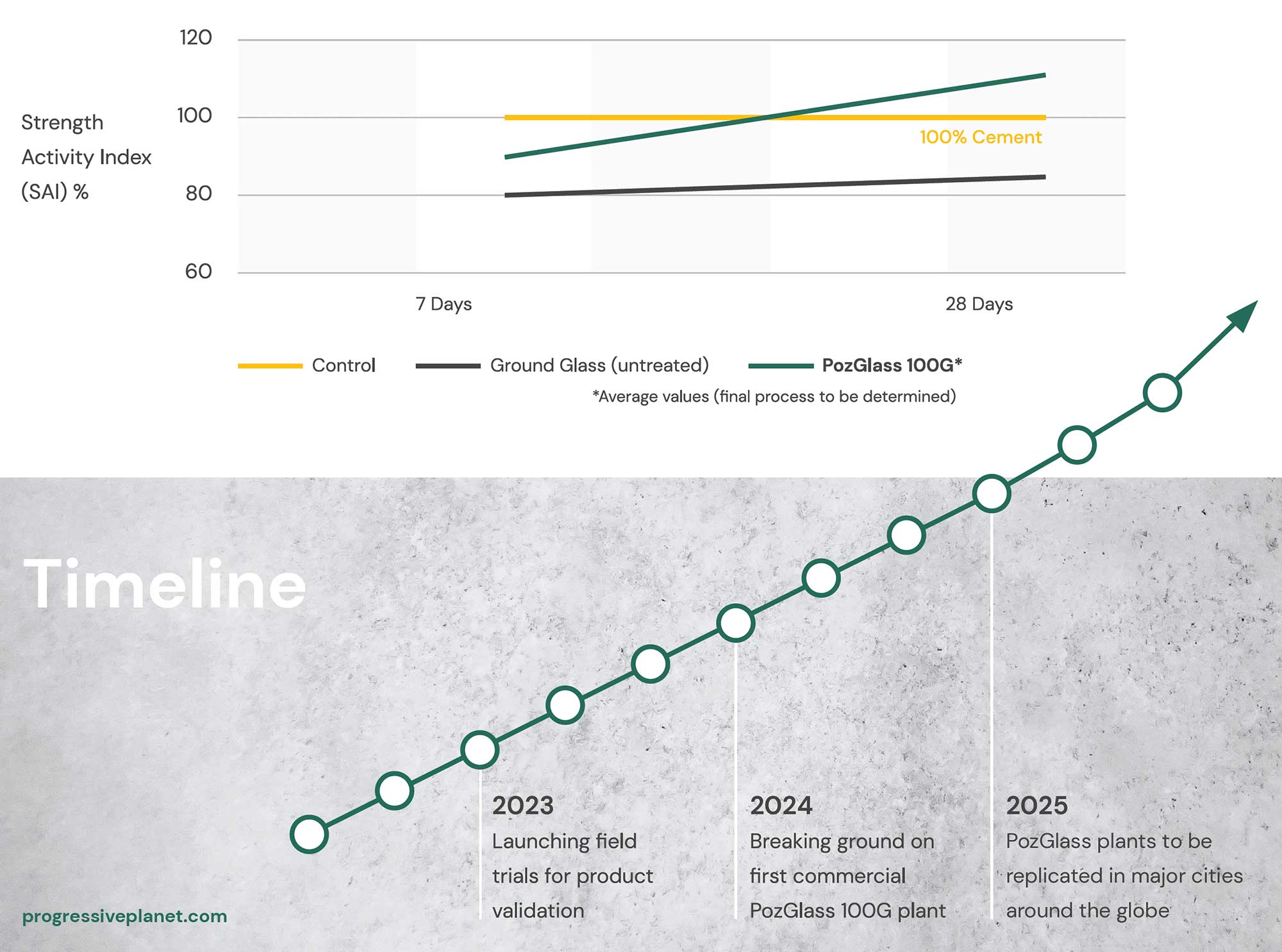

Ground glass has recently been used as a pozzolan to substitute for Portland Cement in concrete. Made by grinding 100% post-consumer glass to a very fine particle size, it is safer to handle than Portland Cement and is stronger and more durable.

Progressive Planet’s PozGlass 100G is a breakthrough that takes the use of glass in cement to a whole new level. It fights climate change and is a far stronger cement.

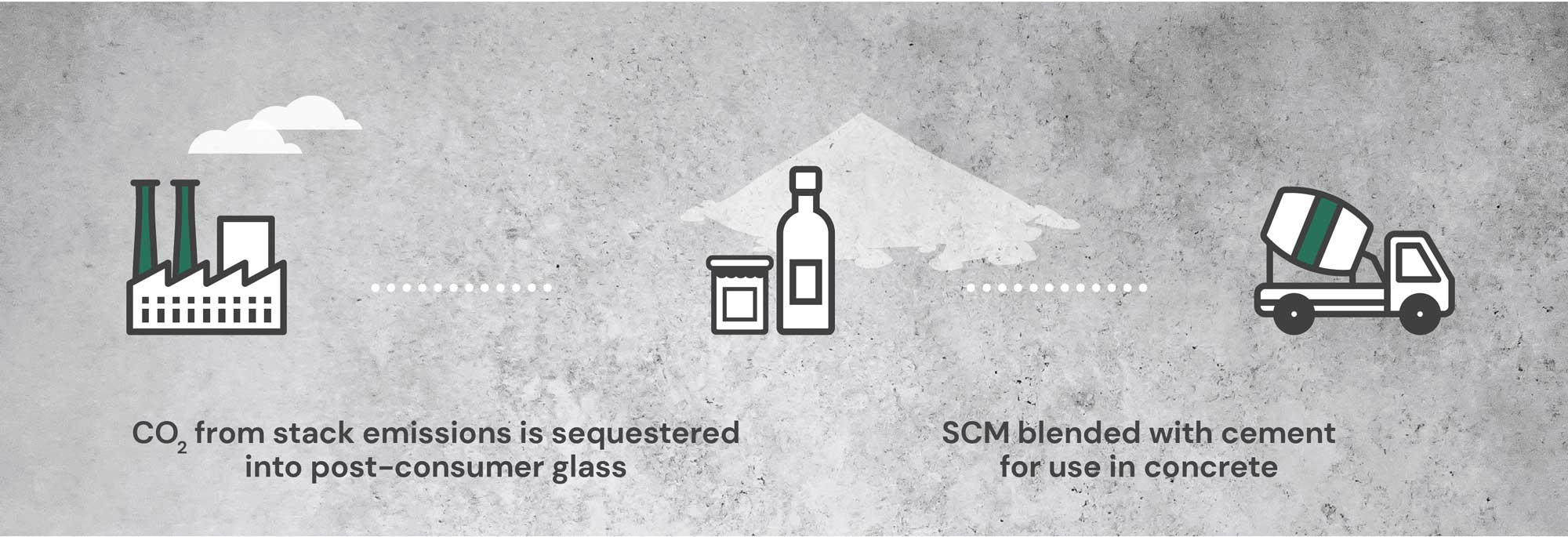

Our patented technology removes sodium from the ground recycled glass and it dissolves. Then we bubble in CO2, creating a sodium carbonate compound. The result is permanent sequestration of large amounts of CO2 that would otherwise be released into the atmosphere.

Another climate benefit is PozGlass 100 replaces a great deal of fly ash, which comes from coal plants and is now used as a pozzolan. One tonne of fly ash releases almost the same amount of CO2 when heated in the cement-making process. By replacing that fly ash with PozGlass, which emits no C02, we further reduce CO2 atmospheric emissions.

It’s one of the biggest steps to help the cement industry meet its target of becoming Net Zero cement by 2050.

Our Natural Pozzolan Solution

Given the future demand for cement, we will eventually run out of enough recycled glass to make enough PozGlass. That’s why we have also created PozZEO, a natural pozzolan, to minimize the use of Portland Cement.

Natural pozzolans occur naturally in the earth’s crust and are a form of volcanic ash, which we harvest from our deposits in southeastern British Columbia.

The Romans used natural pozzolan from Mt. Vesuvius to build their empire. In fact, the word pozzolan is derived from the Italian town of Pozzuoli (now a part of Naples), where the Romans scraped the volcanic ash from surrounding hillsides to make Roman Cement.

The Pantheon, built from that 2,000-year-old breakthrough, is a testament to the strength of Roman Cement. PozGlass and PozZeo build on that 2,000-year-old innovation to make strong, low-carbon cement for today and tomorrow.

PozGlass 100G is a cleantech breakthrough to stop climate change.

By putting finely ground particles of 100-per-cent recycled glass into cement, we dramatically decrease the use of fly ash, the byproduct of coal plants that releases four billion tonnes of CO2 into the air every year.

PozGlass also permanently sequesters CO2 from industry smokestacks by bubbling CO2 into the recycled wastewater, triggering a chemical reaction to create sodium crystals that trap carbon.

It’s very big news for the planet.

Eight per cent of the world’s CO2 emissions now come from making cement. With PozGlass, we can reduce cement’s carbon footprint by as much as 70 per cent. We also make full use of the post-consumer glass we send to landfills every day.

Back to the future with Roman Cement.

PozGlass makes concrete a stronger and more resilient.

That’s because PozGlass is our cleantech innovation of a 2,000-year-old recipe for Roman Cement, which used volcanic ash particles from Pozzuoli, Italy. The testaments to its extraordinary strength are the Coliseum and Pantheon, which still stand in Rome today.

As our planet gets ready for ten billion people, we will need more cement than ever. Consumption of cement in North America has increased by 50% in the last decade alone.

With PozGlass, we can keep building for a Net Zero future.

A Scalable SCM Solution With Kiln Stack Gas Sequestration

Overview of Proprietary Tech:

- Easily integrated into existing cement production facilities

- Captures and sequesters CO2 from cement kiln stack gases

- Further reduces emissions when used as partial replacement for cement

- Diverts post-consumer glass from landfills

- Global adaptability with abundant availability of glass in all major cities

How It Works:

- Enhanced performance of post-consumer glass as an SCM by removing a portion of the sodium in soda-lime glass

- CO2 reacts with removed sodium to form sodium carbonate (permanent carbon sequestration)

- Sodium carbonate is removed, leaving PozGlass 100G